Stock accounting "TOP" company

“TOP” company produces and sells stationery. As our client “TOP” set the following goal: to automate inventory control at wholesale warehouses. That's why the Vostok company set such hardware and software: 1C: Enterprise and Stock 7.7, Windows Server 2003, Windows XP Professional. Besides, the Vostok company equipped working places for merchandise experts, managers, accountants, storekeepers, packers, controllers.

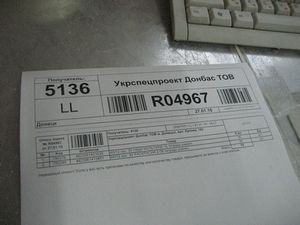

Bar coding of goods, packages, storage.

Bar coding of goods, packages, storage and using of up-to-date devices for bar code reading allow not to use paper documents for warehouse operations. Label printer TTP-248M marks goods and packages. After selection and packaging, boxes and pallets are marked with control label printed on the printer TTP-248M, then packed according to the order product is sent to the shipping zone: the operator checks everything with bar code scanner.

Label printers

For marking large amount of product items – label printer TTP- 248M. The secret is that in spite of the reasonable price printer is equipped with internal winder that can print the necessary number of labels and mark the products, packages with the applicator TOWA 65-30. On those working places where necessity of large amount for marking (warehouse) label printer is used. The potential of the model is up to 5000 labels per shift, it rather satisfies needs of the production and warehouse departments. The construction of the label printer TTP-245 allows easy changing of label tape roll of different sizes, additional studying for personnel is not required. .

Bar code scanners

In different production and working places the Vostok company used various models of bar code scanners. We intentionally didn't insist on the scanner of one producer and offered the client to choose and compare. Three models were tested: Metrologic MS9520, Symbol LS 2208 and OPR-3001-USB. In result of preliminary testing each of the models was used: Metrologic MS9520 were set in the stations of production receiving and sorting, OPR-3001-RS232 – selection and checking of the order, and Symbol LS 2208 – in output control and shipment place. We should especially mention the model OPR-3001: this bar code scanner easily reads “unreadable” bar codes (glassy, tiny and damaged).

Data terminals

The Vostok company used different models of bar code scanners Casio DT-930 and Cipher CPT-8001 in different production and working parts. The employees who select goods, receive the forms with goods. There are order number and bar code of the necessary product in the form. Scanning bar code on the order form, the appropriate document is opened in the terminal – and order report is formed automatically. Actually, only selecting and putting the products onto the carriage, the employee scans bar codes on the packages and goods. The conclusion – it is very convenient and facilitates employees' operations. When the ordered goods were selected, the employee sends formed order to the controlling and packaging table, the data is entered from the terminal. In the computer the list of ordered goods is checked with the data terminal. If there are no differences, employee checks actual availability of products and packs them. During inventory control, data terminals operate in the other mode: employees performing inventory control read bar codes of storage zones, then they scan packages, goods situated on the shelves. Received data is input into the computer and compared. If there are any differences, the employee can see where the product is situated. Then the second check is done. .

The Vostok company used different models of bar code scanners Casio DT-930 and Cipher CPT-8001 in different production and working parts. The employees who select goods, receive the forms with goods. There are order number and bar code of the necessary product in the form. Scanning bar code on the order form, the appropriate document is opened in the terminal – and order report is formed automatically. Actually, only selecting and putting the products onto the carriage, the employee scans bar codes on the packages and goods. The conclusion – it is very convenient and facilitates employees' operations. When the ordered goods were selected, the employee sends formed order to the controlling and packaging table, the data is entered from the terminal. In the computer the list of ordered goods is checked with the data terminal. If there are no differences, employee checks actual availability of products and packs them. During inventory control, data terminals operate in the other mode: employees performing inventory control read bar codes of storage zones, then they scan packages, goods situated on the shelves. Received data is input into the computer and compared. If there are any differences, the employee can see where the product is situated. Then the second check is done. .

Working places in the remote warehouses – operation with 1C via web-interface, bar code scanner OPR-3001-RS-232

Working place for goods sending controller – software.

Licensed software is the way to the success! These are not just words for “TOP”, but reality. Servers operate under operational system Windows Server 2003; PC with operational system Windows XP Professional are set in the employees' working places. Program complex 1C: Trade and Stock 7.7 is the core of the system. The Vostok company significantly changed and complemented the standard configuration 1C: Trade and Stock 7.7..

Address storage of the goods in the warehouse

Storage premises and shelves are divided into zones (cells). Each of zones is marked with polypropylene label with particular number and bar code where cell number is fixed. When goods coming to the warehouse the sorting information is sent to the 1C with data terminal Casio DT930. Then during printing of warehouse document (invoice), the storekeeper knows which zone the selected product is situated in. Besides, the order of goods is formed in such a sequence that storekeeper's movement is optimal, it saves time of goods selection and moving.

Goods inventory

Prompt goods inventory is carried out with data terminals Casio DT930.

Placement optimization

The Vostok Company optimized the checking of storage cells according to the free capacity, size, and storage conditions.

Trade history

Now the client can get full report of goods movements and cells loading. Detailed view of the storage history of each product. Completeness of the packages. Moreover there is opportunity to form complete package, each unit of the package may include different amount of goods.

About our client

«Top» company was founded in 1998 in Dnepropetrovsk. Now “TOP” - is one of the leading stationery producer and wholesale trader in Ukraine.

There are such subsidiaries in the company:

- plants producing notebooks in Dnepropetrovsk and Shklo town;

- the range of products is rather wide: exercise books on the bracket, spiral notebooks, exercise books with adhesive assembly, albums and notebooks;

- factories producing Christmas decorations – artificial trees, tinsels;

- production line of branded sticky tape;

- “Company TOP” trading house.

The company sells the goods of own production and imports under its own trademarks:

- TM “1 Veresnya” - stationery and exercise books for schoolchildren;

- TM “Zoshit Ukrainy” - notebooks, exercise books;

- TM “Yes!” - notebooks of “Premium” class;

- TM “Datum” - office stationery of budget class;

- TM “Leo” - office stationery of “premium” category;

- TM “Novogodko” - new year products and decorations, artificial trees, tinsels;

- TM “Felicita” - items for interior decoration;

- TM “Ecopack” - packing and sticky tape.

Besides, “TOP” is official distributor of well-known Russian factories “Luch” and “Gamma” manufacturing products for children creativity.

Contacts:

- 11 Kashtanovaya Street, Dnepropetrovsk, 49051, Ukraine.

- Telephone: (056)7900708, (056)7900709,

- Site:

- www.top.dp.ua